Search by posts

Calendar

Industry News

By Admin

By Admin

What is the difference between polyester and spun polyester?

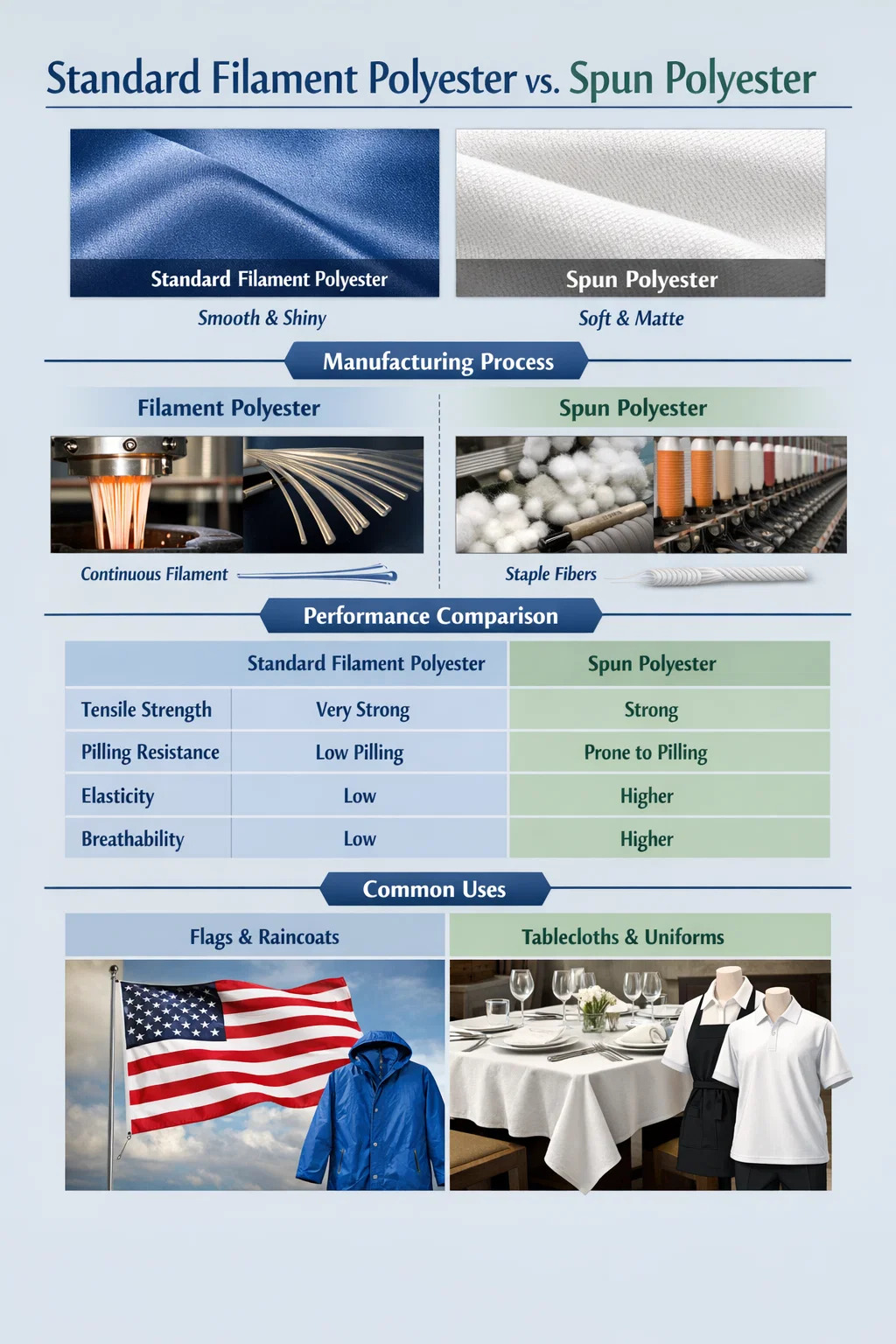

Content The primary difference between standard polyester and spun polyester lies in the fiber length and the resulting texture. Standard polyester (often called filament polyester) consists of continuous long strands, making it smooth, shiny, and slippery. In contrast, spun polyester is made by cutting those long filaments into short "staple" fibers and twisting them together, creating a fabric that feels soft, matte, and remarkably similar to natural cotton. Standard polyester starts as a molten polymer forced through a spinneret. The result is a continuous filament. Think of it like a never-ending strand of silk or a fishing line. Because the fiber is unbroken, the surface is perfectly uniform, reflecting light easily and offering zero friction. To create spun polyester, these long filaments are intentionally chopped into short pieces, usually ranging from 1 to 4 inches in length. These pieces are then "spun" using traditional spinning methods—much like how wool or cotton is processed. This twisting creates a yarn with tiny "hair" ends protruding from the surface, which drastically alters the physical properties of the finished textile. When choosing between these two, you are often balancing comfort against sheer tensile strength. The hospitality and textile industries have largely moved toward spun polyester for items like napkins and uniforms. A primary reason is color retention. Because the spun fibers have more surface area and a textured finish, they hold dyes more effectively than the slick surface of filament polyester. Furthermore, in heavy-use environments, spun polyester is preferred because it doesn't "pick" or snag as easily as filament threads. If a filament thread is snagged, the entire long strand can pull, ruining the fabric's appearance. In a spun fabric, the broken-up fibers isolate the damage. Imagine a fancy dinner. A filament polyester napkin would slide off your lap repeatedly because it is too smooth. A spun polyester napkin stays in place, absorbs the wipe of a hand better, and feels like expensive linen, yet can be bleached and washed hundreds of times without losing its shape or vibrant color. Both types are incredibly easy to care for, but spun polyester requires slightly more attention to heat. Because of the exposed fiber ends, excessive heat in a dryer can cause the "fuzz" to singe or become slightly rough.Direct Conclusion: The Core Distinction

Manufacturing Process: From Liquid to Thread

Filament Polyester Production

Spun Polyester Engineering

Performance and Durability Metrics

Comparative Analysis Table

Characteristic

Standard Filament Polyester

Spun Polyester

Touch / Hand Feel

Smooth, Silky, Cold

Soft, Warm, Cotton-like

Visual Luster

High Shine

Matte / Dull

Breathability

Low (can feel sweaty)

Higher (air pockets in yarn)

Common Uses

Flags, Linings, Raincoats

T-shirts, Tablecloths, Bedding

Why Choose Spun Polyester for Professional Use?

A Practical Example: The Napkin Test

Maintenance and Care Realities