Search by posts

Calendar

Industry News

By Admin

By Admin

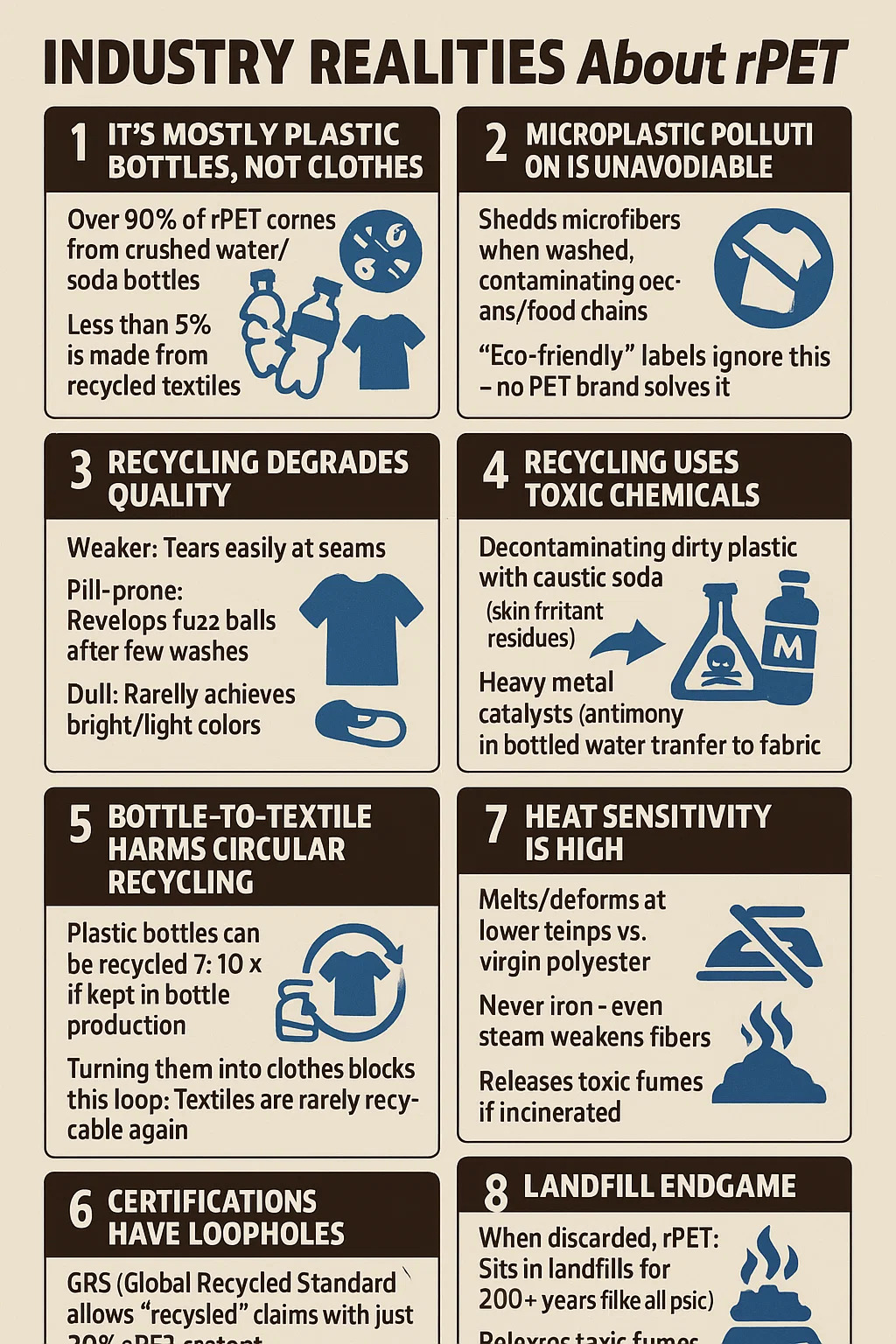

Facts you should know about recycled polyester?

About recycled polyester (rPET) based on industry realities:

1. It's Mostly Plastic Bottles, Not Clothes

Over 90% of rPET comes from crushed water/soda bottles.

Less than 5% is made from recycled textiles—despite marketing claims.

2. Recycling Degrades Quality

Each recycle shortens fibers, making fabric:

Weaker: Tears easily at seams.

Pill-prone: Develops fuzz balls after few washes.

Dull: Rarely achieves bright/light colors.

3. Microplastic Pollution is Unavoidable

Sheds microfibers when washed, contaminating oceans/food chains.

"Eco-friendly" labels ignore this—no rPET brand solves it.

4. Bottle-to-Textile Harms Circular Recycling

Plastic bottles can be recycled 7-10× if kept in bottle production.

Turning them into clothes blocks this loop: Textiles are rarely recyclable again.

5. Recycling Uses Toxic Chemicals

Decontaminating dirty plastic requires:

Caustic soda (skin irritant residues).

Heavy metal catalysts (antimony in bottled water transfers to fabric).

6. Certifications Have Loopholes

GRS (Global Recycled Standard) allows "recycled" claims with just 20% rPET content.

"Ocean Plastic" often uses coastal trash (<1% from actual oceans).

7. Heat Sensitivity is High

Melts/deforms at lower temps vs. virgin polyester.

Never iron—even steam weakens fibers.

8. Landfill Endgame

When discarded, rPET:

Sits in landfills for 200+ years (like all plastic).

Releases toxic fumes if incinerated.