Search by posts

Calendar

Industry News

By Admin

By Admin

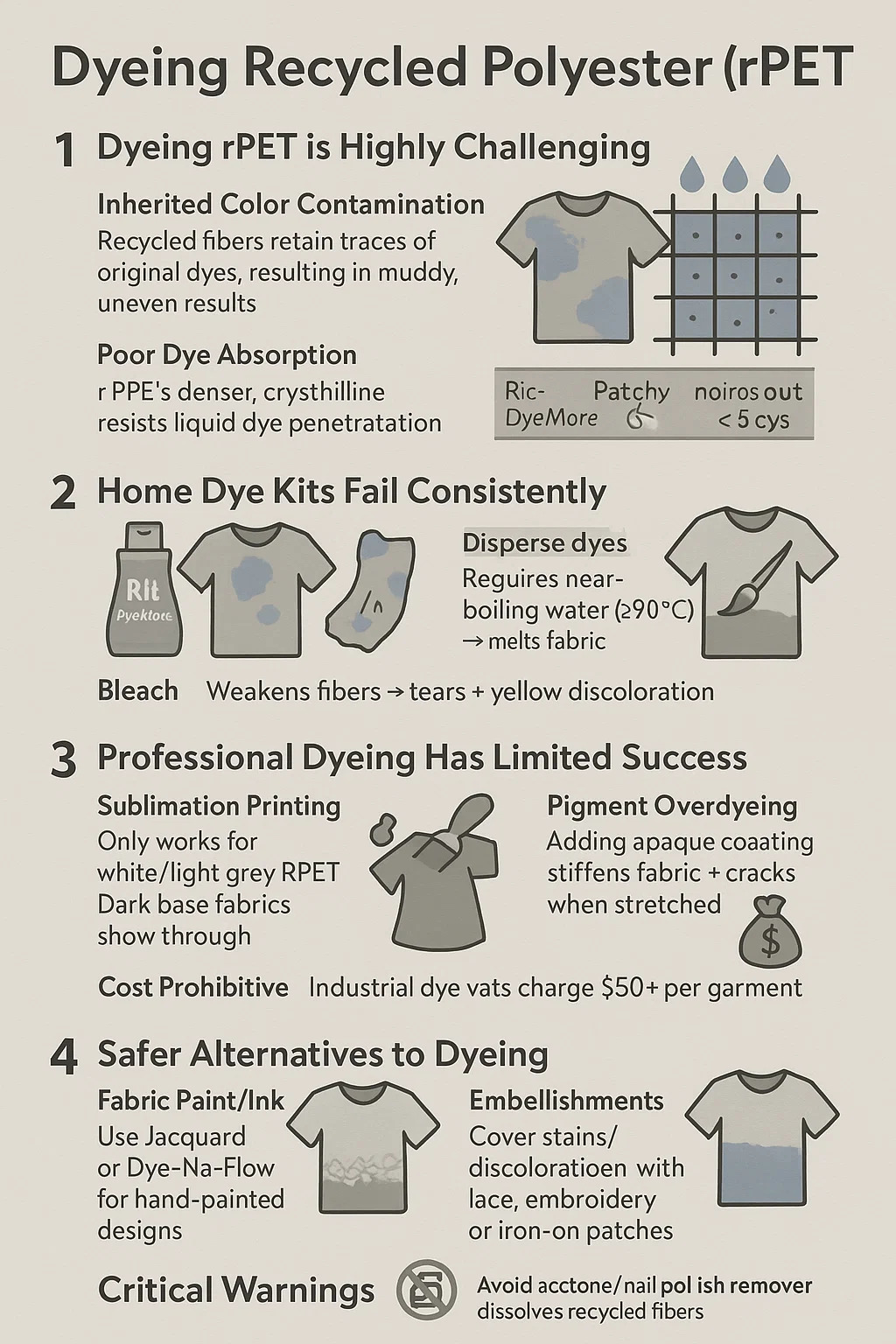

Can i dye this recycled polyester dress?

Here's a straightforward breakdown of dyeing recycled polyester (rPET), based on textile industry realities:

Content

1. Dyeing rPET is Highly Challenging

Inherited Color Contamination: Recycled fibers retain traces of original dyes (blues/greys from plastic bottles), causing muddy, uneven results.

Poor Dye Absorption: rPET's polymer structure is denser and more crystalline than virgin polyester, resisting liquid dye penetration.

2. Home Dye Kits Fail Consistently

| Method | Result on rPET |

|---|---|

| Rit DyeMore® | Patchy color; washes out in <5 cycles |

| Disperse dyes | Requires near-boiling water (≥90°C) → melts fabric |

| Bleach | Weakens fibers → tears + yellow discoloration |

3. Professional Dyeing Has Limited Success

Sublimation Printing: Only works for white/light grey rPET; dark base fabrics show through.

Pigment Overdyeing: Adds opaque coating (like paint) → stiffens fabric + cracks when stretched.

Cost Prohibitive: Industrial dye vats charge $50+ per garment for inconsistent results.

4. Safer Alternatives to Dyeing

Fabric Paint/Ink: Use Jacquard or Dye-Na-Flow for hand-painted designs (test on seams first).

Embellishments: Cover stains/discoloration with lace, embroidery, or iron-on patches.

Dip-Dye Ombré: Only dye hem/cuffs 2-3cm deep to avoid fabric stress.

5. Critical Warnings

Never use boiling water – rPET deforms at 70°C+ (lower than virgin polyester).

Avoid acetone/nail polish remover – dissolves recycled fibers.

Heat-setting ruins elasticity: Ironing "fixes" dye but makes fabric brittle.