Search by posts

Calendar

Industry News

By Admin

By Admin

What is recycled polyester?

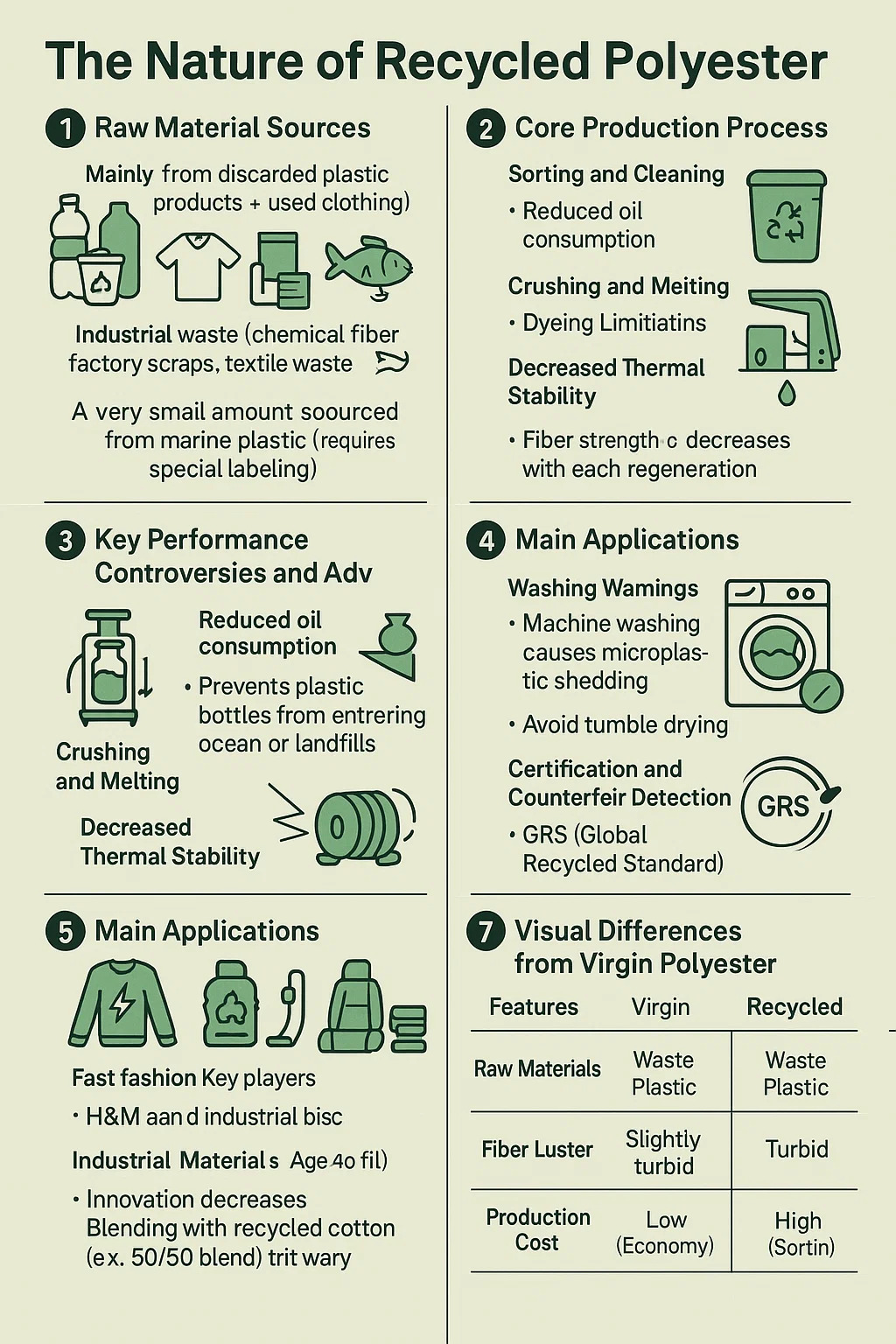

The Nature of Recycled Polyester

1. Raw Material Sources

Mainly from discarded plastic products:

Post-consumer waste: beverage bottles, food packaging, and used clothing (containing polyester).

Industrial waste: chemical fiber factory scraps and textile waste.

A very small amount is sourced from marine plastic (requires special labeling).

2. Core Production Process

Sorting and Cleaning: Removal of labels and glue residues, and high-temperature sterilization.

Crushing and Melting: Plastic bottles/fabric are shredded and then melted at high temperatures to form polyester chips.

Repolymerization and Spinning: The melt passes through a spinneret to restructure the fiber structure and spin new yarn.

Note: This does not involve oil extraction, unlike virgin polyester.

3. Key Performance Characteristics

Strength approaches that of virgin polyester: The recycling process minimizes damage to the molecular chain, and abrasion resistance is retained at least 90%.

Dyeing Limitations: Due to the presence of color in the raw material, it is primarily used for darker colors; light colors require the addition of concealer masterbatch.

Decreased Thermal Stability: Repeated melting reduces heat resistance, and high-temperature ironing can easily harden the product.

4. Environmental Controversies and Advantages

Core Advantages:

Reduced oil consumption: 1 ton of recycled polyester saves approximately 5 tons of crude oil.

Prevents plastic bottles from entering the ocean or landfills (degradation takes 400 years).

Unresolved Challenges:

The washing process generates microplastic wastewater (existing filtration technology only captures 60%).

Unable to be infinitely recycled: Fiber strength decreases by approximately 15% with each regeneration.

5. Main Applications

Fast Fashion Key Players: Widely used in sportswear and down jackets by brands such as H&M and ZARA.

Industrial Materials: Automotive interiors, safety ropes, and shipping pallets (for high-strength applications).

Innovation Directions:

Blending with recycled cotton (e.g., a 50/50 blend) to mitigate the wrinkle-prone nature of pure cotton.

Using recycled ocean plastic in outdoor equipment (backpacks, tents) is more marketing gimmick than real value.

6. Consumer Notices

Washing Warnings:

Machine washing causes microplastic shedding; use a shed-proof laundry bag.

Avoid tumble drying: High temperatures accelerate fiber aging. Certification and Counterfeit Detection:

GRS (Global Recycled Standard) certification requires ≥20% recycled content to be labeled.

The "Ocean Plastic" label lacks unified regulation; be wary of greenwashing.

7. Visual Differences from Virgin Polyester

Features: Virgin Polyester Recycled Polyester

Raw Materials: Petroleum Extracted Waste Plastic

Fiber Luster: Uniform and Translucent Slightly Turbid (Contains Trace Impurities)

Production Cost: Low (Economy of Scale) High (Sorting and Cleaning Costs Account for 60%)

Carbon Emissions: High 30%-50% Lower than Virgin Polyester

| Characteristic | Virgin Polyester | Recycled Polyester |

| Raw Material | Petroleum refining | Plastic waste |

| Fiber Luster | Uniformly translucent | Slightly dull/hazy (traces of impurities) |

| Production Cost | Low (economies of scale) | High (sorting/cleaning = ~60% cost) |

| Carbon Emissions | High | 30-50% lower than virgin |

| Molecular Integrity | Intact polymer chains | Partially degraded chains |

| Recyclability | Can be recycled | Downcycled (quality loss per recycle) |

| End-of-Life Impact | Persistent microplastic pollution | Delays but doesn’t prevent plastic waste |